How to Properly Polish and Finish Lock Picks for Optimal Performance

2024-12-05 09:23

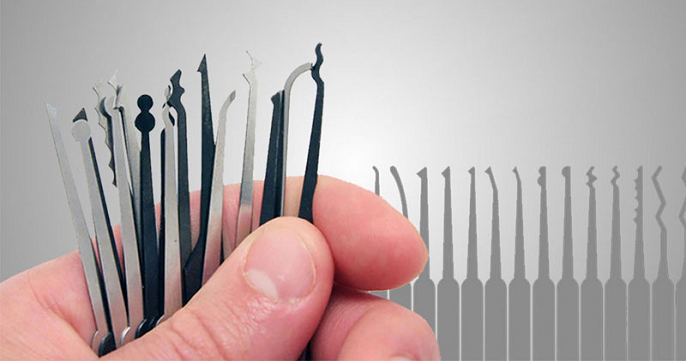

Polishing and finishing your lock picks is an essential step for ensuring that your tools work smoothly, feel responsive in your hands, and last longer. Many beginner and intermediate lock pickers may not realize how critical a smooth, polished pick is to lockpicking, but the difference it can make is substantial. In this guide, we will walk through the reasons for polishing your picks, the materials you need, and the process of achieving a professional finish.

Why Polish Lock Picks?

During the manufacturing process, lock picks often have rough or uneven edges left over from production. These imperfections can cause your picks to catch on the internal components of a lock, such as the pins, causing friction and resistance. The rough edges can also reduce the "feel" of the pick, making it harder to detect subtle feedback during the picking process. In some cases, these imperfections can even damage both your pick and the lock, such as over-lifting pins or catching on other internal components.

Polishing your picks eliminates these issues, resulting in a smoother, more refined tool. A properly finished pick will glide effortlessly through the lock internals, offering improved tactile feedback that can help you fine-tune your technique and achieve faster, more precise lock manipulation.

Materials Needed

To properly polish and finish your Lock Picks Sets, you’ll need a few basic materials. Fortunately, most of these items are easy to acquire and inexpensive:

Sandpaper (various grits, starting at 600 and up to 2000 or higher)

Metal polish

WD-40 (for protection and rust prevention)

Lubricating oil (for use with sandpaper)

Protective gear (face mask, goggles, gloves)

Elbow grease (for manual effort)

The sandpaper will be used to gradually smooth and refine the surface of the pick, starting with coarse grits and working up to finer ones. Metal polish helps give the pick a mirror-like finish, and WD-40 provides a rust-resistant layer to protect the tool after polishing.

Step-by-Step Process for Polishing Lock Picks

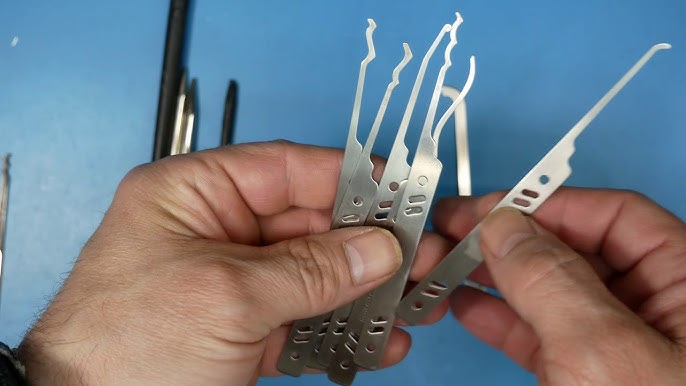

1.Start with Coarse Grit Sandpaper (600 Grit)

Begin by sanding the surface of your lock pick with 600 grit sandpaper. You want to focus on the areas that feel rough or have any visible imperfections. Sanding will help to remove any burs or scratches from the manufacturing process. Be sure to apply even pressure and avoid over-sanding the pick, as this can make it too thin and weaken the tool. Sand in small circular motions, ensuring that the entire surface is covered.

2.Move to Medium Grit (1000-1500 Grit)

Once the rough edges are smoothed out with the 600 grit sandpaper, it’s time to move to a finer grit, such as 1000 or 1500. This grit will help further refine the pick's surface and eliminate any remaining imperfections from the previous step. Continue sanding until you no longer see any scratches from the 600 grit paper. Again, be mindful not to over-sand.

3.Refine with Fine Grit (2000 Grit or Higher)

For the final step of sanding, use 2000 grit sandpaper (or even 3000 if you’re aiming for an extremely smooth finish). This fine grit will polish the surface, giving it a smooth, shiny appearance. As you move through the finer grits, you should notice that the pick begins to take on a reflective sheen, which means you are on the right track. It’s essential to remove all the marks from the previous grits as you go.

4.Lubricate Sandpaper to Reduce Friction

A helpful trick is to apply a small amount of lubricating oil to the sandpaper. This reduces friction, making the sanding process smoother and preventing the metal dust from becoming airborne. Not only does this improve safety by minimizing exposure to metal particles, but it also helps to achieve a cleaner finish. Always work in a well-ventilated area or outdoors to ensure your safety.

5.Apply Metal Polish for a Mirror Finish

Once sanding is finished, it's time to use metal polish to achieve a shiny, mirror-like finish. Apply the polish with a clean cloth or soft pad, using circular motions to work it into the surface of the pick. Wear gloves, as metal polish can irritate the skin. Keep polishing and buffing until you’re happy with the appearance, and if necessary, repeat the process several times to reach the desired level of shine.

6.Apply WD-40 for Protection

Once your pick has been polished to your liking, take a small amount of WD-40 on your fingertip and gently rub it over the surface of the pick. This will add a protective layer that prevents rust and corrosion. WD-40 helps to keep your lock pick in excellent condition, especially if you live in a humid environment or plan to store the tools for a while.

7.Final Inspection

After polishing and applying the WD-40, inspect your pick closely. It should have a smooth, reflective surface without any visible scratches or imperfections. The edges should feel smooth to the touch, with no rough spots. If you find any areas that need further attention, you can repeat the sanding and polishing process.

Conclusion

Polishing and finishing your Lock Picks is an easy but highly effective way to improve both the performance and longevity of your tools. By following these simple steps—sanding, polishing, and protecting your picks—you ensure a smoother, more precise lockpicking experience. With a little time, patience, and effort, your lock picks will feel like a brand-new set of tools—ready to take on any lock.

Like Us on Facebook to enjoy 5% discount

Like Us on Facebook to enjoy 5% discount